Low Leakage Switch Matrix

RM1010-LLC

Low Leakage Relay Matrix Mainframe

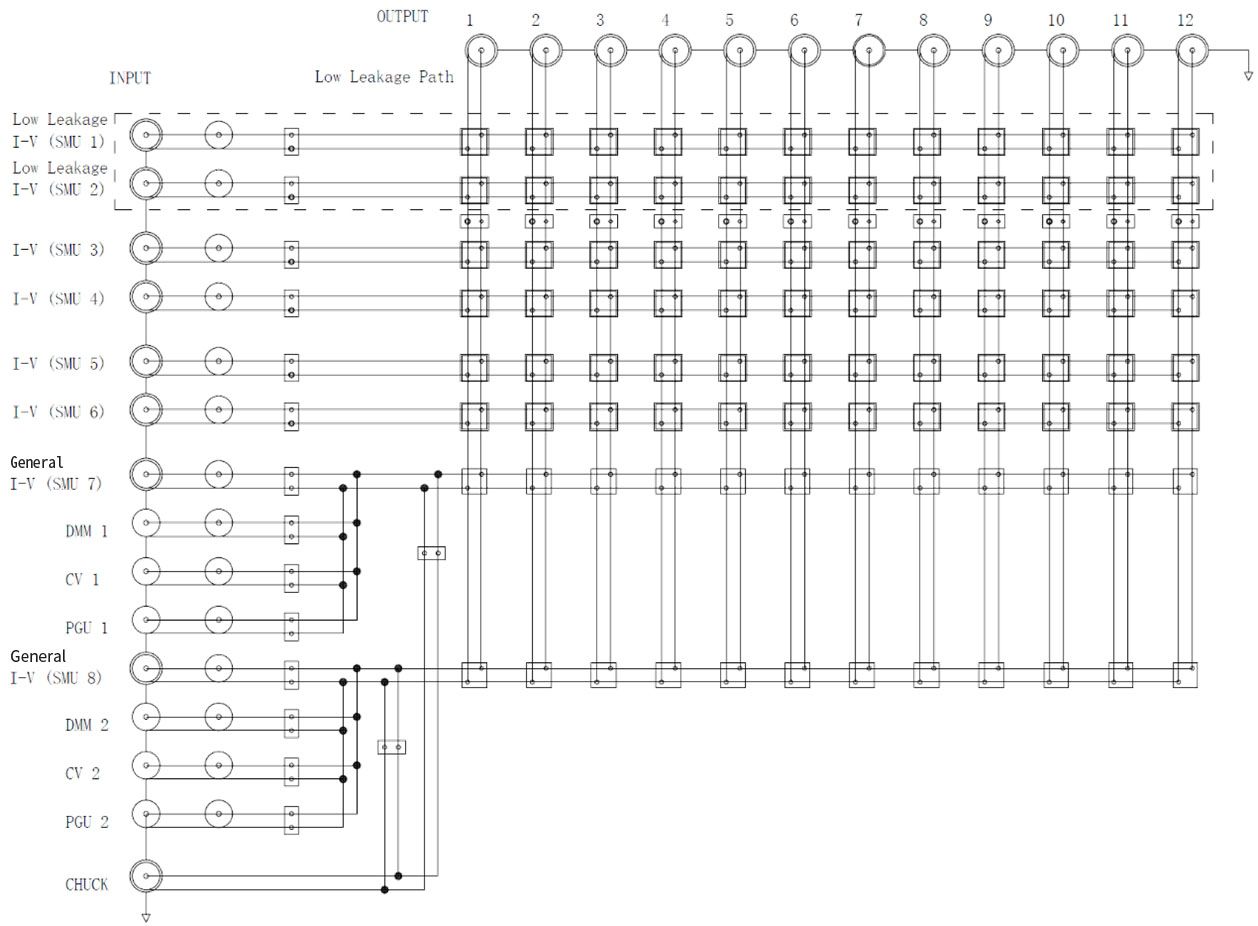

RM1010-LLC is a 4-slot semiconductor switch matrix that can meet high-speed semiconductor test applications by integrating S3022F benchtop or S2012C PXle SMU. Easy-to-use GUI helps to speed up the development of new test functions and simplify system integration. It supports traditional SCPI commands, enabling easy and fast programming of test code. It can support multi-machine parallel connection to achieve test efficiency improvement and cost reduction.

Features

Multi-channel Flexible Measurement

Supports for 2-channel low leakage current input

Low Leakage Current

The minimum achievable leakage current <100 fA

Rapid Measurement

The establishment time of weak current <3.5s

High Relay Contact Life

The switch life >10^8 times

10MHz BW

Optimize the transmission bandwidth of C-V and HF channels

Supports 2 Control Methods

Run the upper computer GUI software on the PCFunctions and Advantages

Precise, Consistent Results

Supports 2 channels of low leakage current input, the whole machine supports 14 inputs and 48 outputs.

|

Specification |

|

2(Low Leakage I-V Port) 6(General I-V Port) 2(C-V Port) 2(DMM Port) 2(PGU Port) |

| Ouput Channels | 12/24/36/48 | |

| Max. Current Rating | 1 A | |

| Max. Voltage Rating |

200V(Channel to Ground) 300V (Channel to Channel) |

|

|

|

0.6 Ω(Low Leakage I-V Port) 1.0 Ω(General I-V Port) 1.0 Ω(C-V, HF Port) |

|

|

|

1013 Ω(Low Leakage I-V Port) 1012 Ω(General I-V Port) 109 Ω(C-V, HF Port) |

|

|

Typical Data |

Offset Current | <100fA(Low Leakage I-V Port) <1000pA(General I-V Port) |

|

|

<80μV(Low Leakage I-V Port) <110μV(General I-V Port) <110μV(C-V, HF Port) |

|

| Channel Crosstalk Capacitance | <0.3pF/CH |

Similar recommendation

Follow

Name

E-mail verfication code

Phone

Password

Confirm Password

E-mail address

E-mail verification code

New Password

Confirm Password