PXIe Source Measure Unit

S2016C

Single-Channel PXIe SMU

The S2016C is a high precision, compact, cost-effective, single channel PXIe Source/Measure Unit (SMU) with the capability to source and measure both voltage and current. It has maximum ±200 V, ± 1A (DC), ± 3A (pulse), and 20W constant power sourcing capability. It supports conventional SMU SCPI commands for easy programming. It supports most standard PXIe chassis and multi-card synchronization.

The S2016C can be integrated into production test environment to achieve test efficiency improvement and cost reduction.

Features

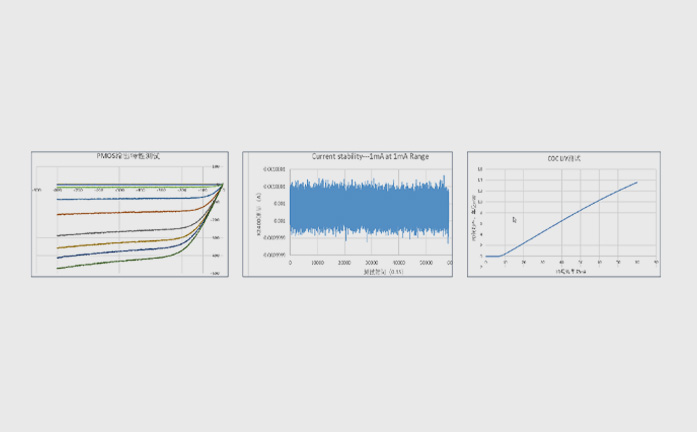

High-precision

Resolution up to 1fA/100nV

High Range, High-speed Measurement

Range: ±200 V, ±1 A(DC), ± 3A (pulse)

Adaptive PFC System

Utilize Adaptive PFC

Building A Single-channel Testing System

Based on standard PXIe chassis, easy to expandFunctions and Advantages

5 Functions In One Card

Voltage source

Test Various Devices

Capture More Measurement Data

♦ 6-and-a-half-bit digital resolution: the accuracy is equivalent to a 6-and-a-half-bit digital multimeter.

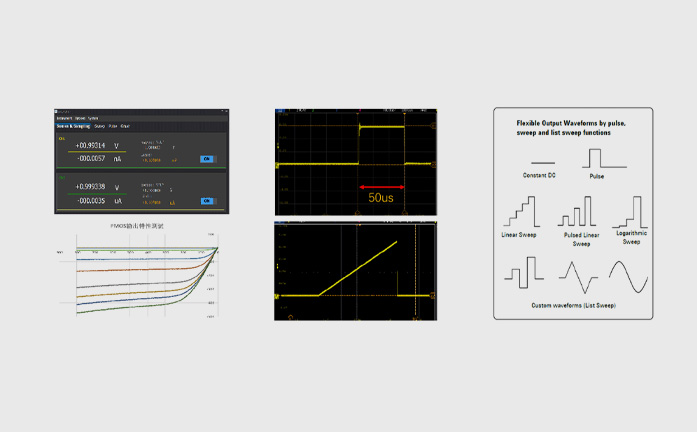

Rich Scanning Functions

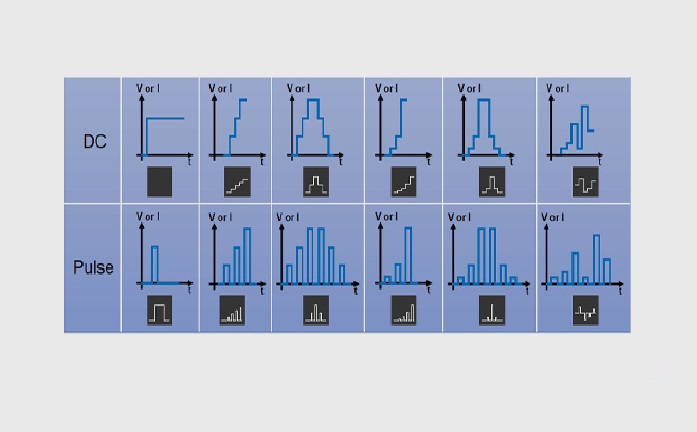

DC I-V Output Capability

Pulse I-V Output Capability

|

Voltage Accuracy |

Range |

Measurement Resolution |

Accuracy (1 year) ± (% reading+offset)[1] |

Typical Noise (RMS) 0.1 Hz-10 Hz |

|

±200 V[2] |

100 μV |

0.03%+10 mV |

400 μV |

|

|

±40 V |

10 μV |

0.03%+2 mV |

100 μV |

|

|

±20V |

10 μV |

0.03%+1 mV |

50 μV |

|

|

±2 V |

1 μV |

0.03%+100 μV |

10 μV |

|

|

±0.6 V |

100 nV |

0.03%+50 μV |

2 μV |

|

|

Temperature Coefficient |

±(0.15 × accuracy)/℃ (0℃-18℃, 28℃-50℃) |

|||

|

Overshoot |

<±0.1% (typical, normal mode, step is 10% to 90% range, full range, resistive load) |

|||

|

Noise 10Hz-20MHz |

<5 mVrms, (20V voltage source, 1A resistive load) |

|||

[1] Accuracy calculation example: To test the accuracy of a 600mV range with a 120mV

output, the tolerance is:

[2] This instrument has a potentially dangerous high voltage (±210 V) output to the HI / Sense HI / Guard terminals. To prevent electric shock, relevant safety precautions must be taken before powering on. Do not connect the Guard terminal to any output, including shorting it to the chassis ground or output LO, as this will damage the instrument

|

Current Accuracy |

Range |

Measurement Resolution |

Accuracy (1 year) ± (% reading+offset) |

Typical Noise (RMS) 0.1 Hz-10 Hz |

|

±3 A[3] |

1 μA |

0.03% + 2mA |

20 μA |

|

|

±1 A |

100 nA |

0.03% + 90 μA |

4 μA |

|

|

±100 mA |

10 nA |

0.03% + 9 μA |

600 nA |

|

|

±10 mA |

1 nA |

0.03% + 900 nA |

60 nA |

|

|

±1 mA |

100 pA |

0.03% + 90 nA |

6 nA |

|

|

±100 μA |

10 pA |

0.03% + 9 nA |

700 pA |

|

|

±1 μA[4] |

100 fA |

0.03% + 200 pA |

20 pA |

|

|

±10 nA[4][5] |

10 fA |

0.06% +9 pA |

600 fA |

|

|

±1 nA[4][5] |

1 fA |

0.1% +3 pA |

60 fA |

|

|

±100 pA[4][5] |

1 fA |

0.3% +1 pA |

30 fA |

|

|

Temperature Coefficient |

±(0.15 × accuracy)/℃ (0℃-18℃,28℃-50℃) |

|||

|

Overshoot |

<±0.1% (typical. normal mode. step is 10% to 90% range, full range, resistive load) |

|||

[3] 3A range is available only for pulse mode, accuracy specifications for 3A range are typical

[4] For measuring very weak small currents, it is recommended to continue using triple coaxial cables for connection. If triple coaxial terminals are converted to ordinary wiring output methods, it will affect the instrument

[5] Additional specification conditions: 10PLC setting

|

Minimum Programmable Pulse Width |

100 μs |

|

Pulse Width Programming Resolution |

1 μs |

|

Pulse Width Programming Accuracy |

± 10 μs |

|

Pulse Width Jitter |

2 μs |

|

Pulse Width Definition |

The time from 10% leading to 90% trailing edge as follows |

|

Item |

Maximums |

Maximum Pulse Width |

Maximum Duty Cycle |

|

1 |

0.1 A/200 V |

DC, no limit |

100% |

|

2 |

1 A/20 V |

DC, no limit |

100% |

|

3 |

3 A/66.6 V |

1 ms |

5% |

|

4 |

3 A/160 V |

400 μs |

2% |

|

Source |

Maximum Output |

Typical Rise Time[6] |

Typical Settling Time[7] |

Test Load |

|

Voltage |

160 V |

800 μs |

1.2 ms |

No load |

|

5 V |

50 μs |

100 μs |

No load |

|

|

Current |

3A~100 μA |

100 μs |

250 μs |

Full load[8] |

| 100 μA | 150 μs | 400 μs | Full load[8] | |

|

1 μA |

800 μs |

1.2 ms |

Full load[8] |

|

|

10 nA |

5 ms |

20 ms |

Full load[8] |

|

|

1 nA |

10 ms |

50 ms |

Full load[8] |

|

|

100 pA |

100 ms |

500 ms |

Full load[8] |

[6] Leading edge, the time from 10% leading to 90% leading

[7] The time required from Pulse out 0 to reach within 1% of final value

[8] Test condition: Normal, resistive load 6V maximum output

|

Source |

Range |

Output Settling Time[9] |

Condition |

||

|

Fast[10] |

Normal |

Slow |

|||

| Voltage |

200 V | <600 μs |

<1.2 ms |

<2 ms |

Time required to reach within 0.1% of final value at open load condition. Step is 10% to 90% range |

|

40 V |

<200 μs |

<400 μs |

<900 μs |

||

|

20 V |

<100 μs |

<200 μs |

<600 μs |

||

| 2 V | <300 μs |

<300 μs |

<300 μs |

||

| 0.6 V | <300 μs |

<300 μs |

<300 μs |

||

| Current |

3 A~1 mA |

<150 μs |

<200 μs |

<0.8 ms |

Time required to reach within 0.1% (0.3% for 3A range) of final value at short condition. Step is 10% to 90% range |

|

100 μA |

<150 μs |

<250 μs |

<0.8 ms |

||

| 1 μA |

<1 ms |

<1 ms |

<1 ms |

||

|

10 nA |

<10 ms |

<10 ms |

<10 ms |

||

|

1 nA |

<50 ms |

<50 ms |

<50 ms |

||

|

100 pA |

<500 ms |

<500 ms |

<500 ms |

||

[9] Output transition speed: Fast, Normal, Slow. Users can adjust the APFC parameters based on the load characteristics to obtain precision, and fast output characteristics

[10] Slow mode is recommended for overshoot sensitive equipment, Fast mode may have overshoot on output in some condition

Similar recommendation

Follow

Name

E-mail verfication code

Phone

Password

Confirm Password

E-mail address

E-mail verification code

New Password

Confirm Password