Silicon Photonics

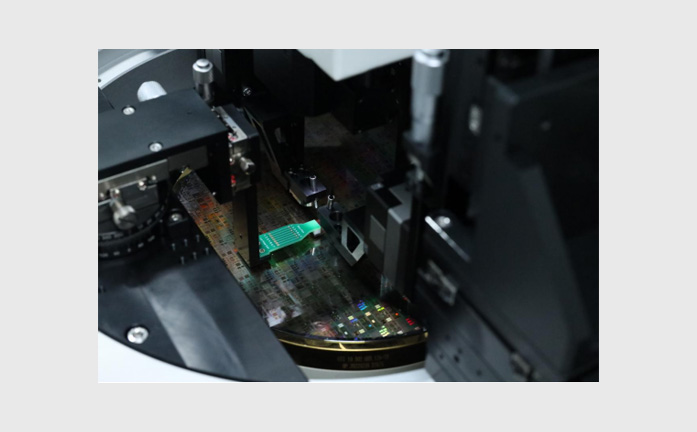

sCT9001

SiPh Wafer Test System

Features

Automatic/Semi-automatic

Supports automatic and semi-automatic wafer loading and unloading

Wafer Size

Supports 8-inch and 6-inch wafers

Test Temperature

Supports the test temperature range from room temperature to 150 ℃ (other temperatures can be customized)

Test Function

Supports optical-optical test, photoelectric test and electrical parameter test

DC/AC

Supports DC and AC test

Grating Vertical Coupling

Grating coupling, FA coupling, and edge coupling

High Efficiency

For different types of chips, supports rapid replacement of different types of pin cards

Software Function

The software supports the addition of customer database and MES functionsFunctions and Avantages

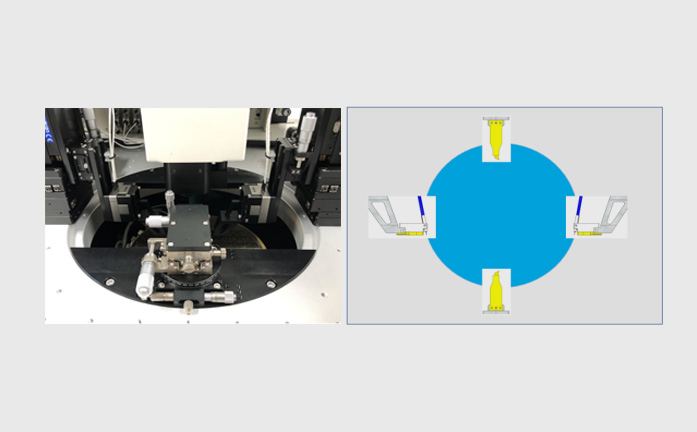

High Accuracy Probe Station

Wafer loading mode supports fully automatic mode and semi-automatic mode operation, which is suitable for laboratory verification and mass production.

The fully closed-loop high-accuracy motion control system is provided with automatic accuracy compensation function and its positioning accuracy is up to 3μm.

The special mechanism design and calibration system can make the wafer on chuck have better planarity and better perpendicularity in Z direction of probe.

A high-definition zooming CCD configured on the system can make the power on PAD clearly visible and display low-magnification and high-magnification multi-view screens at the same time.

The built-in integrated shock-proof design is adopted which can isolate the external vibration and ensure a good test stability.

Coupling Test Module

The coupling test module includes coupling optical probe, DC probe and RF probe.

The optical probe supports single-channel coupling and dual-channel coupling.

The optical probe is provided with a high-precision altimeter to ensure the consistency of the height from the incident fiber end face to the chip surface between different chips.

The optical fiber coupling module is composed of a three-dimensional lead screw motor matched with a three-dimensional high-precision piezoelectric ceramic module to ensure the optical coupling efficiency and the optical coupling repeatability.

The standard high-precision coupling controller configured on the system which can help the system realize the functions of fully closed-loop control and hardware synchronization improve the coupling accuracy and coupling speed.

The design of the probe card holder is more convenient for the replacement of the probe card, which is convenient to quickly replace the probe card for different products or different test items.

|

CHUCK |

Platform |

Material |

Cast iron |

|

Chuck X&Y Axis |

Motor type |

Servo motor |

|

|

Travel range X*Y |

≥240 mm * 340 mm |

||

|

Resolution |

0.1 μm |

||

|

Positioning accuracy |

±2 μm |

||

|

Max speed |

200 mm/s |

||

|

Chuck Z Axis |

Motor type |

Stepper motor |

|

|

Travel range |

≥30 mm |

||

|

Resolution |

0.2 μm |

||

|

Positioning accuracy |

±2 μm |

||

|

Max speed |

30 mm/s |

||

|

Chuck θ Axis |

Motor type |

Stepper motor |

|

|

Travel range |

±8° |

||

|

Resolution |

0.001° |

|

Coupled Module |

Motion and positioning |

Hexapods + Piezo |

6 serial axis +Piezo |

|

Max number of active axes |

9 |

9 |

|

|

Rotation for roll, yaw and pitch |

Automated |

Automated |

|

|

Stepping for X, Y, Z |

Automated |

Automated |

|

|

Rough Positioning |

|||

|

Travel range X,Y,Z |

±17, ±15, ±7 mm |

±15, ±15, ±10 mm |

|

|

Travel range θX, θY, θZ |

±9, ±8.5, ±18° |

±6, ±5, ±6° |

|

|

Minimum incremental motion X, Y, Z |

±0.10, ±0.10, ±0.05 μm |

±0.10, ±0.10, ±0.10 μm |

|

|

Minimum incremental motion θx, θy, θz |

0.05mdeg, 0.05mdeg, 0.1mdeg |

0.01deg, 0.01deg, 0.01deg |

|

|

Fine Positioning |

|||

|

Travel range in X, Y, Z, closed loop |

80 μm |

||

|

Min. incremental motion, open-loop |

0.4 nm |

||

|

Min. incremental motion, closed-loop |

4 nm |

||

|

Alignment Speed |

|||

|

Scanning time of spiraled area scan |

<1.5 s |

||

|

Note |

For vertical coupling only, purchasing the 8-axis system is sufficient. To be compatible with both vertical and edge coupling, the 9-axis system is required |

||

|

Coupling Specification |

Optical coupling speed |

<1.5s @ unilateral coupling |

|

Coupling repeatability |

<0.2 dB (30 times) |

|

|

Optical power stability |

<0.2 dB@5 min |

Similar recommendation

Follow

Name

E-mail verfication code

Phone

Password

Confirm Password

E-mail address

E-mail verification code

New Password

Confirm Password