Date:2022.11.19

Visits:802

Date:2022.11.19

Visits:802

CoC (Chip on Carrier)/CoS (Chip on Sub mount) architecture has become a popular packaging style for diodes/lasers. CoC usually uses customized waffle packs or Gel Paks for transportation and storage, and flows in different processes such as testing and burn-in. Due to the small size of CoC itself, it is very easy to cause damage during assembly and transportation of CoC, including mechanical damage during manual clamping, ESD damage during operation, and pollution caused by introducing other materials during assembly, which seriously affect the quality and reliability of products.

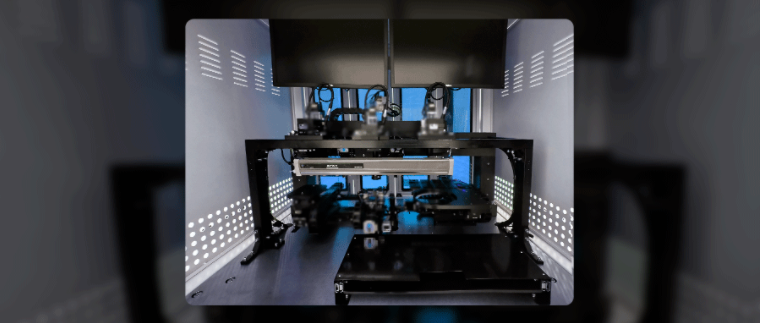

Semight AL6201

Semight AL6201 is an automatic CoC loading and unloading equipment specially designed to cooperate with the CoC burn-in system. The modular design enables rapid installation, disassembly, maintenance and switching of products. The CoC is automatically fed to the burn-in fixture, which greatly reduces manual operation, without EOS, and ensures the product reliability of the customer's CoC production line. At the same time, AL6201 can also be used as a separate blanking and sorting system for bare chips or CoCs.

Product features and advantages

1.

Support the mutual dumping of 4 different chip material boxes

Semight CoC burn-in fixture, customer made vehicle, GelPak, blue film

2.

Support Chip ID identification

3.

Support automatic Bin distribution during blanking according to test results

4.

Single product loading is less than 7s, blanking is less than 6s

System components and functions

1 Positioning camera

Position the CoC on the material box, blue film or carrier clamp;

2 Identification camera

Identify CoC Chip IDs;

3 Suction nozzle

Select the vacuum nozzle to pick up CoC of different sizes;

4 Loading platform

Blue film/GelPak carrier;

5 Clamp

Place semight instrument or customer customized CoC fixture;

6 Handling device

Loading and unloading materials between different vehicles with the help of positioning camera;

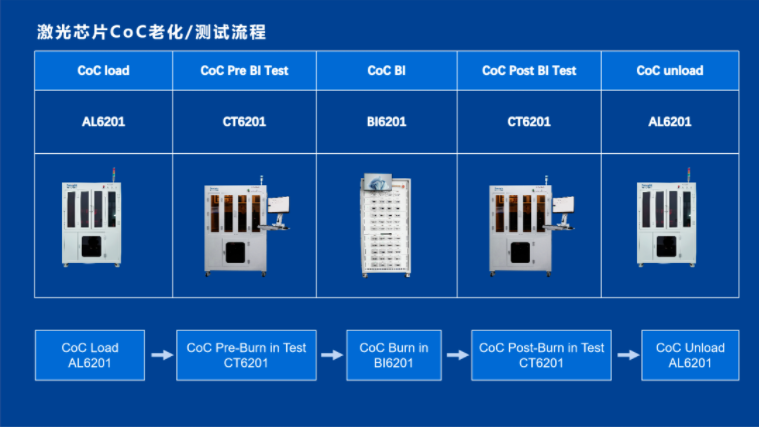

Semight CoC Burn-in Test Solution

Semight provides a complete solution for CoC/CoS loading and unloading, testing and burn-in, adapting to different test temperature requirements, different sizes and different types of semiconductor lasers, greatly improving the test efficiency and reducing the test cost!

Follow

Name

E-mail verfication code

Phone

Password

Confirm Password

E-mail address

E-mail verification code

New Password

Confirm Password